Technologies

Krianvee has the Infrastructure proprietary technologies needed for cost-effective water treatment including recycling and recovery. Our water conservation solutions are being used by major industries around the world for industrial, commercial, and municipal applications. Water optimization is a critical component of all modern establishments given the urgent need to save and recover water. We have the technologies coupled with the know-how and experience to provide customized wastewater treatment solutions.

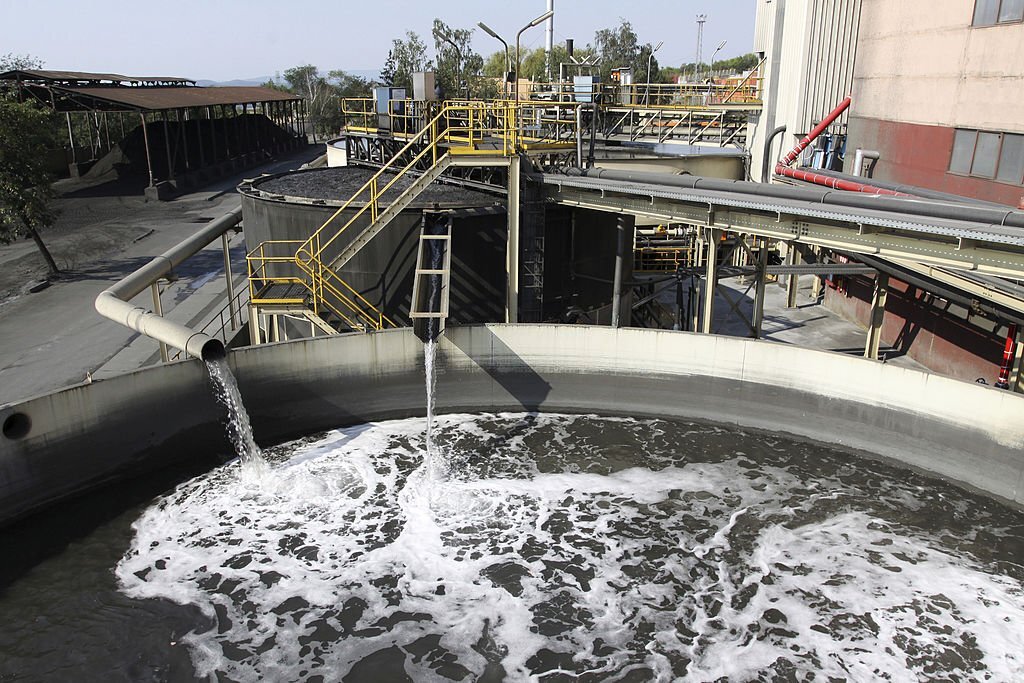

Secondary Wastewater Treatment

Secondary Wastewater treatment is the second stage of wastewater treatment. In primary treatment, suspended solids, colloidal particles, oil, and grease are removed. In secondary treatment, biological treatment is done on the wastewater to remove the organic matter present. This treatment is performed by indigenous and aquatic micro-organisms like bacteria and protozoa which consume biodegradable soluble contaminants like sugar, fat, detergent, and food waste. These processes are sensitive to temperature and with an increase in temperature, the rate of biological reactions increases.

Secondary Wastewater treatment is divided into two different treatment processes:-

Aerobic Treatment:

Aerobic wastewater treatment is a biological treatment that uses oxygen to break down organic matter and remove other pollutants like nitrogen and phosphorus. Aerobic treatment technologies are:

- Activated Sludge Process (ASP) / Extended Aeration System (EAS)

- Sequential Batch Reactor (SBR)

- Moving Bed Bio Film Reactor (MBBR)

- Membrane Bioreactor (MBR)

Anaerobic Treatment:

2. Anaerobic Treatment: Anaerobic treatment is a process where wastewater or material is broken down by micro-organisms without the aid of dissolved oxygen. However, anaerobic bacteria can and will use oxygen that is found in the oxides introduced into the system or they can obtain it from organic material within the wastewater. Anaerobic treatment technology is Up-flow Anaerobic Sludge Blanket Reactor (UASB)

- The scheme of the Extended Aeration process and its mixing regime are similar to that of the completely mixed process.

- The process employs low organic loading, long aeration time, high MLSS concentration, and low F/M. BOD removal efficiency is high.

- Because of long detention in the aeration tank, the mixed liquor solids undergo considerable endogenous respiration and get well stabilized.

- Due to the higher requirement of oxygen, there is an impact on the total operating cost of the system.

- However, the operation is rendered simple due to the elimination of primary settling and separate sludge digestion.

- The Sequential Batch Reactor is a fill and draws an activated sludge system for wastewater treatment.

- Equalization, Aeration, and Clarification all can be achieved using a single batch reactor. SBR system is successful for large industrial effluents.

- The SBR eliminates the need for a secondary clarifier. Although SBR has shown more maintenance in operation since the process is PLC based, it shows higher efficiency and less area requirement for the ETP.

- SBR combines the secondary treatment process and settlement. It is used to reduce the organic matter (BOD and COD), oxygen is bubbled with a mixture of wastewater and activated sludge. After this treatment, the treated water can be discharged on surface water.

A Moving Bed Biofilm Reactor (MBBR) consists of an aeration tank which is similar to an activated sludge tank with special plastic carriers that provide a higher surface area where a biofilm can grow.

Membrane Bioreactor – MBR is the combination of ultrafiltration (UF) and activated sludge process. MBR produces effluent of high quality which can be discharged to surface water for reuse. It can be retrofitted in existing installations.

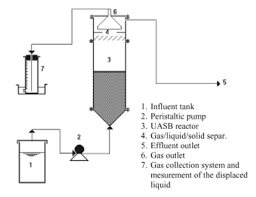

- Upflow Anaerobic Sludge Blanket (UASB) technology also known as UASB reactor is a form of the anaerobic digester

- UASB reactor is a methane-producing digester, which uses an anaerobic process forming a blanket of granular sludge and is processed by the anaerobic micro-organisms

- In the case of higher organic loads, UASB helps to reduce the higher extent of organic loads and further aerobic treatment can be taken for the remaining loads

- Generally, during the treatment of the UASB reactor, the substrate passes through an expanded sludge bed which contains a high concentration of biomass first

- Generally, during the treatment of the UASB reactor, the substrate passes through an expanded sludge bed which contains a high concentration of biomass first

- The sludge circulation and mixing are done through sludge recirculation cum disposal pump. The excess granular sludge is wasted into sludge drying beds