Technologies

Krianvee has the Infrastructure proprietary technologies needed for cost-effective water treatment including recycling and recovery. Our water conservation solutions are being used by major industries around the world for industrial, commercial, and municipal applications. Water optimization is a critical component of all modern establishments given the urgent need to save and recover water. We have the technologies coupled with the know-how and experience to provide customized wastewater treatment solutions.

INDUSTRIAL WASTEWATER EVAPORATORS

Evaporation technology is used to turn the liquid form of a chemical substance such as water into its gaseous-form/vapour in order to separate undesirable substance from the liquid and purify it. In water treatment processes like desalination and zero liquid discharge, industrial wastewater evaporators are used to remove the desirable drinking water from the undesired solute/product-salt.

Evaporation technology works on almost all kind of effluents but it has always been an energy-intensive process.

At Krianvee, we introduce you to the world’s most economical, sustainable, highly effective and fully automated polymeric film technology based on mechanical vapour re-compression and multi-effect distillation techniques.

Polymeric Film Technology is patented by Krianvee and uses polymeric films in heat exchangers instead of metal. The polymeric film requires less amount of heat and smaller boiler size. Operating cost of the system is low and the energy saving is around 80% more than the conventional metallic wastewater evaporators by using this technology is lower than the conventional metallic evaporators.

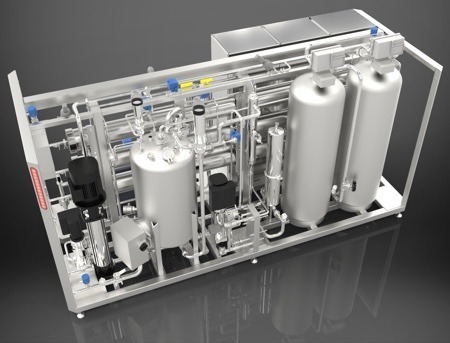

Mechanical vapour recompression evaporator (MVRE)

MVRE is an energy recovery evaporator which compresses a low-pressure vapour and produces a low volume of vapour with high pressure and temperature. In MVRE influent is heated with steam and the vapour produced is compressed and sent to a heat exchanger where it gets condensed and gives pure water at the outlet. Generally, MVRE is used before MEE to reduce the TDS concentration of influent.

This system is available in polymeric film technology.

FEATURES

- MVRE allows convenient retrofitting in existing projects in order to derive a maximum advantage over MEE

- Lowers the capex of boilers as MVRE system requires a much lesser capacity boiler

- No need for major civil construction, only vessel foundation is required

- A fully automated system with remote monitoring, no dedicated manpower required

- VFD system can be used to allow flexibility in operations and energy usage optimization

- Standard and high-quality products are used to increase system longevity

- Available in standard capacities of 50, 100, 150, 200, 250, 300, 450 and 500 KLD systems. Bigger capacity systems are available on request.

- Area required for installing the system in the range of 225 m² to 1350m2

MED process consists of multiple stages in which water is fed and heated by steam in tubes. The water evaporates and the steam flows into the next stage, heating and evaporating more water. In this, the process energy is reused from each stage. Compared to other processes energy used in MED is much low. Generally, MED is used for the production of potable water from the sea and brackish water.

The MED process operates at low temperatures, which results in:

- Small to medium-sized plant sizes

- Reduced scaling risk

- Low thermal energy consumption

- Reduced operating costs

- In MEE sequences of vessels are used. Here water is boiled in the vessels, each held at a lower pressure than the last, because the boiling temperature of the water decreases as pressure decreases the vapour boiled off in one vessel can be used to heat the next, and only the first vessel (at the highest pressure) requires an external source of heat

- In MEE the first vessel is fed with the high-pressure steam to evaporate the wastewater

- The evaporated water in the form of steam produced after boiling the effluent in the first vessel is used to evaporate effluent in the second vessel at atmospheric pressure. Evaporated water from the second vessel is used to evaporate wastewater in the third stage under vacuum

- Finally evaporated water from the third stage is condensed in the steam condenser using cooling water on the other side

- Condensate from the entire three vessels is collected in condensate receiving tanks, which is pure water and hence reused in the process

- Concentrated mass from each effect is collected in the crystallizer where inorganic salts are precipitated along with the organic contaminants. This mass is filtered in activated carbon filter and the filtrate is recycled back to process

This process can handle which is very difficult for other processes. This method separates volatile from the less volatile components using indirect heat transfer and mechanical agitation of the flowing product under controlled conditions.

MSF distils the water by using heat exchanger and condensate collector at different stages. MSF has number of stages. With the sequence have a cold end and a hot end with having intermediate stages at intermediate temperature. In MSF water is heated at the maximum temperature through one end. Then the heated water enters the brine heater heating it much more. Water flows back through valves into stages that have lower temperature and pressure. Evaporation of water at each stage would be 15%. Mostly this process is used at desalination plants.